Factories

Labs

Million Sq. Ft.

Million Products/Yr

The Power of Collaboration

We are a highly experienced team of industry leaders specializing in designing, sourcing, and manufacturing top-tier products. Our expertise spans various sectors such as medical, consumer, EV, robotics, outdoor, sports, and technical gear. We provide innovative case and cover solutions by collaborating closely with our clients. Leveraging our diverse development team and state-of-the-art materials and automation, we craft the perfect solution for your product. “Protect your brand, Protect your Product“

-

Experienced Design Team

-

Best in Class Manufacturing

-

Optimized Supply Chain

-

Softgoods / Cut & Sew

-

EVA / Thermoplastic/ Injection Molding

-

Mixed Media Manufacturing

-

OEM Carry Case Solutions

-

Factory Direct Value Pricing

Services

Design & Develop

- Design Thinking Approach

- User Research

- Concept Development and Iteration:

- Industrial Design

- Prototyping and Testing

- Design for Manufacturing (DFM)

- Packaging and Branding Design

- Post-Launch Support

- Continuous Process Improvement

Sourcing

- Supplier Identification and Qualification

- Supplier Relationship Management

- Cost Analysis and Negotiation

- Supply Chain Diversification

- Quality Assurance and Control

- Ethical Sourcing and Compliance

- Logistics and Supply Chain Management

- Risk Management

- Continuous Improvement

- Market Research and Trend Analysis

Manufacturer

- Quality Craftsmanship

- Certifications

- Innovative Design

- Sustainable Practices

- Strict Quality Control

- Wide Material Selection

- Advanced Production Techniques

- Flexible Production Capacity

- Competitive Pricing

- Compliance to Standards

- Reliable Diverse Supply Chain

Prototyping

Softgoods Prototypes

- Functional Cut and Sew

- EVA foam molding

- Thermoforming

- 3D Print assembled sewn into softgoods

- Leather

- Silicon

- USA and Asia sample locations

Project Management

- Clear Project Goals and Objectives

- Comprehensive Project Planning

- Stakeholder Management

- Resource Allocation and Management

- Risk Management, Alternate factory sites

- Effective Overseas and US Team Collaboration

- Task and Timeline Management

- Quality Assurance

- Change Management

- Post-Launch Evaluation and Lessons Learned

Consulting

- Diversification Support (Out of China to alternate Asia locations)

- Design and Engineering Support

- Risk Mitigation

- Regulatory and supply chain vulnerabilities

- Competitive Counter Quoting

- Research and Development

- Specification Development

- Packaging Solutions

- Factory Evaluation

- Global Clientele Support

- Supply Chain Optimization

Strategic Partners

Logistics / E-Commerce

- Logistics

- Fulfillment – Pick/Pack/Ship

- Retail or bulk pack

- Consumer direct, warehouse replenishment

- Buy / Sell Process

- Warehousing

- Inventory Management

Reverse Logistics

- Centralized returns

- Triage and disposition

- Advance Exchange Swap

- Warranty claim management

- Replacement stock management

Repair & Refurbishment

- Repair / Refurbish

- Whole Unit Repair & Return

- Consumer Direct/Bulk

- Component Level Repair

- Complete Remanufacturing

- Parts Reclamation

- Parts Refurbishment

Team

Carsten Fitzner

CEO

carsten@fwdgp.com

30+ years’ experience in leading new product development, sales growth, business development and client relationship management in Medical and Consumer ,across North America, Asia, and Europe.

Mark Philips

COO

mark@fwdgp.com

30+ years of direct international sourcing for companies as a director of global sourcing for THULE and Case Logic. Expertise in product development and design, factory production oversight along with extensive first-hand QA/QC expertise.

Stefan Martin

Director of Design

15+ years of experience, a holistic approach to design from concept to production. Expert in ideation, rendering, 3D modeling/ CAD, prototyping of softgoods and EVA molded foams.

Rachel Deng

Creative Director

18 years of experience in Silicon Valley and proven track record of success designing and implementing for clients across different industries, platforms, and technologies.

Mike Edmunds

Engineering manager MS Mechanical, Engineering

MS in Mechanical Engineering since 2001 , expert in 3D design The ability to create Rapid Design concepts in Consumer Electronics, Bioscience, Government Defense, and Medical greatly improves speed to market.

Peter Julber

Technical Engineer, Softgoods Expert, Sample Lab

30 years in the sewn products industry, expertise and ability to develop softgoods protypes quickly. Master in technical sewing of softgoods needs. Having over 5,000 items repaired or created solutions.

Todd Austin

Managing Director

30+ years of experience in leading early stage companies to define and implement go to market product strategies and scalable operations. Extensive hands on experience in bringing new products to market while leveraging a global supply chain. Broad product development background, launching products in several categories: high volume consumer products – Apple/MacBook, medical – Cepheid, healthcare – BAM/UDP Labs.

Alex Jorgeson

Packaging Engineer

Twenty-year professional with dynamic experiences as a Packaging Engineer and Procurement Specialist in medical device development and high-volume consumer electronics. MS in Project Management Medical Device Packaging and Consumer packaging

Travis Barkel

Board President

Michigan Association of Healthcare Resource & Materials Management international healthcare supply chain leader and innovator with a passion for developing people and successful, lean processes. Skilled client service and supply chain expertise capable of guiding client and supplier relationships to efficiency, profitability, and satisfaction for a best-in-class outcome.

History

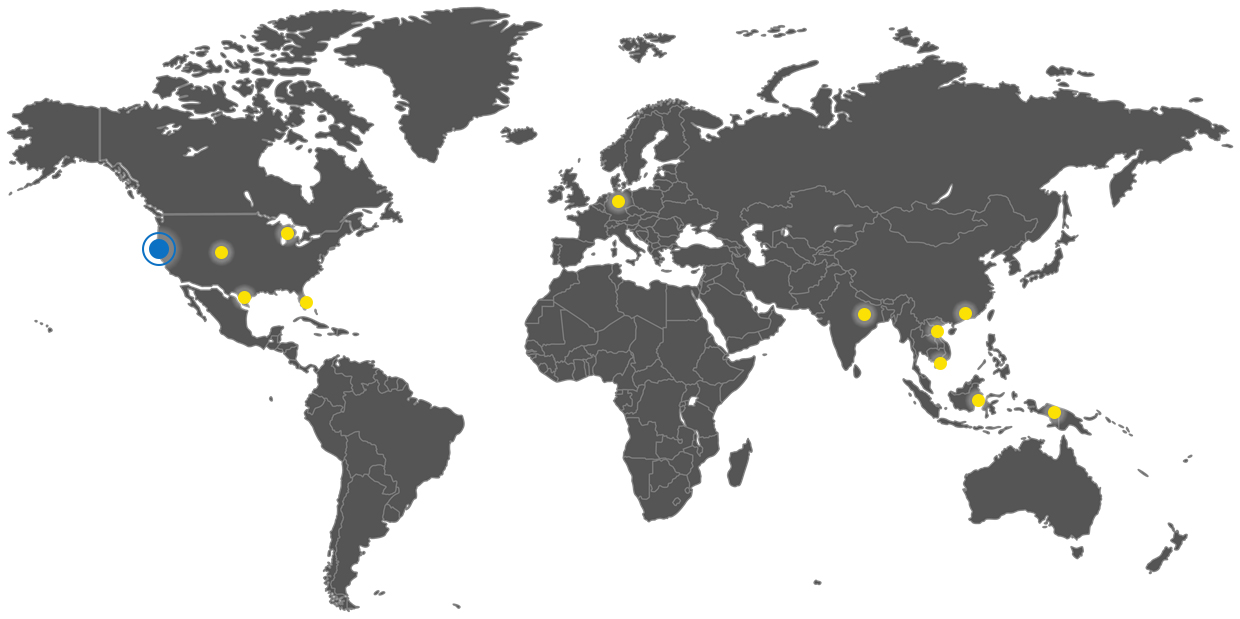

Locations

Palo Alto, California, United States

California | Colorado | Texas | Michigan | Florida

Germany | Indonesia | India | China | Vietnam | Cambodia

Contact Us

With over 30 years of experience, our team can support your new or existing , eva molded foam, injection molding, cut and sew soft goods case challenges to Protect your product and Protect Your brand.

Our Partners

For companies ready to shift or grow, ronin is the right minds in the room when you need them.

Control Plastics and Metals is a prototype and production partner specializing in custom plastic and metal components, injection molds, assemblies, and sub-assemblies—serving customers worldwide for over 40 years.

World leader in textile manufacturing, delivering sustainable, biodegradable, high-performance woven and stretch fabrics for global apparel, bags, footwear, industrial, protective, and home applications—backed by advanced R&D and decades of expertise.

FAQ

Engineered softgoods

What are Engineered and Technical softgoods?

Softgoods refer to products primarily made from soft, flexible materials, offering benefits in ergonomics, cushioning, durability, and aesthetics. Examples include backpacks, sporting equipment, health monitoring devices, and safety gear, among others. These are made from materials like special fabrics, molded EVA foams, rubber, elastomers, and gels, differing from products made of plastics, metal, or composites.

In many instances, softgoods integrate hard components or electronics, such as sensors, displays, and controls, exemplified by the Oculus. Their construction involves various techniques like industrial sewing, ultrasonic or RF welding, computer-controlled knitting or weaving, injection and compression molding, mechanical fastening, and bonding.

The design process of soft goods includes unique considerations. Material selection, seam allowances, pattern design, and component assembly play key roles. For instance, in compression molded foam parts, as seen in a Bose headset case or barcode scanner holster, details like fabric lamination and integration into a sewn assembly must be considered.

Placement Text

What are Engineered and Technical softgoods?

Softgoods refer to products primarily made from soft, flexible materials, offering benefits in ergonomics, cushioning, durability, and aesthetics. Examples include backpacks, sporting equipment, health monitoring devices, and safety gear, among others. These are made from materials like special fabrics, molded EVA foams, rubber, elastomers, and gels, differing from products made of plastics, metal, or composites.

In many instances, softgoods integrate hard components or electronics, such as sensors, displays, and controls, exemplified by the Oculus. Their construction involves various techniques like industrial sewing, ultrasonic or RF welding, computer-controlled knitting or weaving, injection and compression molding, mechanical fastening, and bonding.

The design process of soft goods includes unique considerations. Material selection, seam allowances, pattern design, and component assembly play key roles. For instance, in compression molded foam parts, as seen in a Bose headset case or barcode scanner holster, details like fabric lamination and integration into a sewn assembly must be considered.

Copyright © 2023, Forward Global Partners.